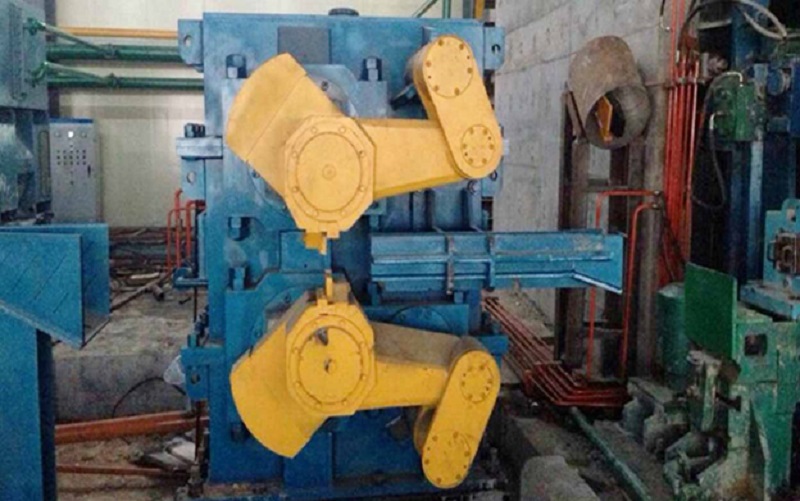

What is the most significant steel production? How can steel mills produce various steel products? What are their needed and demanded devices, machines, tools, and systems? Steel mill shears are like giant machines that have different steel products. These machines can work around 365 days a year without any stops. The shears require iron, coal, and other raw materials. These materials will get to the shears via the ship or rail. The shearing machines have their own unique methods. Based on the reports, the iron coal first enters the coking plant. Then, the device will bake the iron coal at a high temperature for over 20 hours. As the process shows, the resulting material needs to be excellent. Sometimes, this process can be performed with water. According to a professional in the field of steel mill shears, the rested materials must become problematic for the blast furnace. Stay with us to get more information about shearing machines available in steel mills.

What Do Steel Mill Shears Do?

As we have said, steel mill shears or shearing machines primarily work with iron coal. Therefore, this kind of coal must be prepared for further processing in the blast furnace.

Moreover, the scorching air can be followed by the shears. Sintering is also an important step during the shearing machine’s operation. Note that this device can even help the melting process, which begins with iron coals and additives.

These items and materials help fill the blast furnace from the above. Each still mill uses various amounts of materials per day. We mean the available materials will be important and useful in the working process of the shearing machines.

Hot air is also essential when using shearing machines in steel mills. Note that the hot air comes from below, leading to complex reactions at high temperatures. The oxygen decreases over time during the shearing machine performance.

What Are the Useful Materials for the Steel Mill Shears?

Shearing machines play an essential role during the steel mill production process. Various components are available for this machine, most resulting in molten iron.

Various materials will be available, such as iron coal, hot air, molten iron, and many other materials during the shearing machines’ performance. Some materials can avoid any dangerous production process.

It is good to know that every 1 to 2 hours, the temperature of the steel mill furnace will get higher, and this process may affect the shearing machines, too. According to the gathered reports, the shearing machines will produce the steel in the melt shape to make them flexible and forgeable.

Additionally, the amount of carbon will decrease when using the shearing machines. The final step of steel mill production will be done in the converter. Remember that these machines try to work environmentally friendly and perform the most effective and practical steps during the steel mill production procedure.

Various materials are available and useful for shearing machines to get the best final result and production. As the steel mill reports show these machines play vital role in the steel mill procedures.